Measuring and Reducing the Carbon Footprint of Modular Homes in California: A Path Toward Sustainable Living

By Joy Line Homes California

As California leads the nation in climate action, housing is under increasing pressure to evolve. Buildings are responsible for nearly 40% of global emissions, and reducing that number has become an urgent priority. Joy Line Homes, a modular home builder based in Santa Cruz County, is taking a thoughtful approach to addressing the carbon footprint of residential construction. By merging efficient factory production, sustainable materials, and solar-ready design, Joy Line Homes is charting a path toward low-carbon living that aligns with California’s ambitious environmental goals.

Understanding the Carbon Footprint of a Home

A carbon footprint measures the total greenhouse gas emissions, primarily carbon dioxide, methane, and nitrous oxide, associated with a product or activity. For homes, this includes everything from the materials used in construction to the energy consumed during daily operation. Each stage of a building’s life contributes differently: the extraction of materials, transportation, assembly, energy use, maintenance, and even end-of-life disposal all leave measurable carbon impacts.

In traditional construction, inefficiencies at the job site, excessive material waste, and transportation of crews can add significant emissions. Modular homebuilding changes this equation. By producing homes in a controlled factory environment, Joy Line Homes minimizes waste, optimizes energy use, and ensures consistent quality. Still, like every builder, there’s room to go further, and that’s where careful measurement and innovation come in.

Why Measuring Matters

Before emissions can be reduced, they must be measured. For Joy Line Homes, a carbon analysis begins with a complete inventory of materials and energy flows. Each wall panel, beam, and window carries its own embodied carbon value, the sum of emissions from its manufacture, transport, and assembly. Likewise, every stage of construction, from delivery trucks to cranes, adds operational emissions. Understanding these inputs allows Joy Line to make data-driven choices about how to build better.

Once homes are occupied, the focus shifts to operational energy, heating, cooling, lighting, and appliances. In California, where the grid is steadily greening through renewable energy, electrified homes with efficient systems can reach near-zero operational emissions. Joy Line’s designs, which comply with Title 24 energy codes and integrate solar readiness, already perform well on this front. The next step is reducing embodied carbon through smarter material choices and manufacturing strategies.

Breaking Down the Home’s Carbon Profile

To understand where carbon emissions come from, we can divide a home’s life cycle into five main categories. These categories together define the environmental impact of any structure.

Embodied Emissions: These stem from the extraction and production of raw materials—everything from lumber to insulation. Prefabrication can minimize waste here by cutting precisely measured materials in controlled conditions, eliminating the inefficiency of jobsite cutting and disposal.

Construction Emissions: On-site work requires trucks, cranes, and other machinery that use fuel. Because modular homes arrive mostly assembled, Joy Line’s on-site emissions are considerably lower than conventional builds. Shorter timelines mean fewer trips, less idling equipment, and reduced waste.

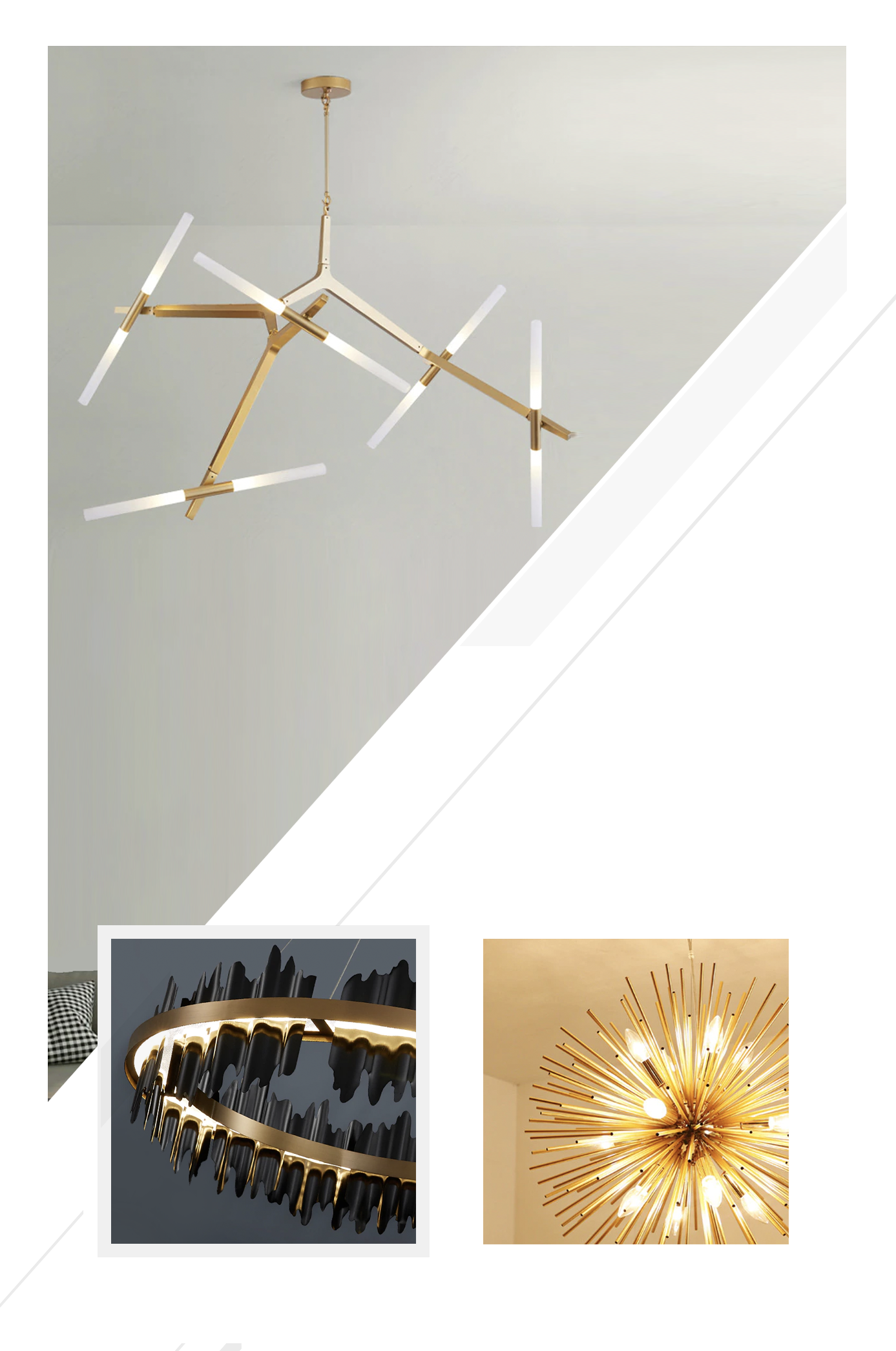

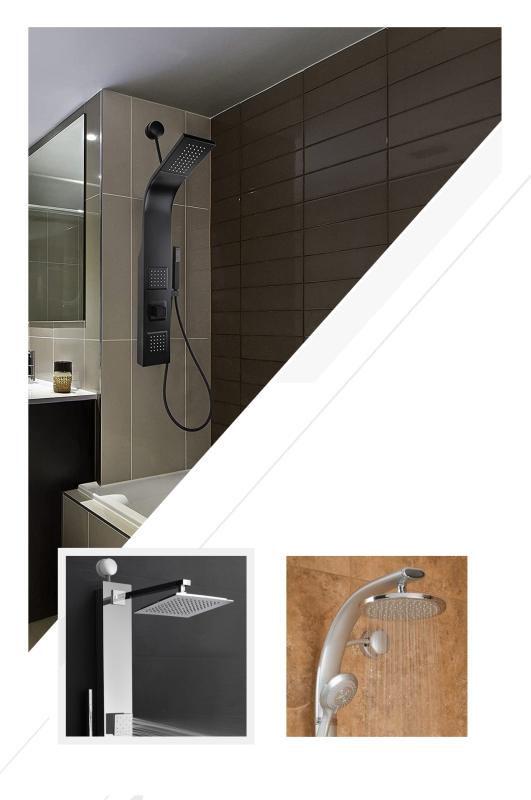

Operational Emissions: This is where homeowners feel the biggest long-term impact. High-efficiency HVAC systems, low-energy lighting, and tight building envelopes keep emissions and utility costs low for decades.

Maintenance and Replacement: Durable materials and well-engineered systems extend a home’s lifespan and reduce the need for replacements, cutting future embodied carbon.

End of Life: Modular homes can be disassembled more easily than traditional ones, making material recovery and recycling possible. This circular approach can further reduce emissions and landfill waste.

How Joy Line Homes Can Lead in Carbon Reduction

Reducing a carbon footprint involves tackling both the direct and indirect sources of emissions. For Joy Line Homes, the advantage lies in the precision of its factory model and its flexibility to adopt new technologies quickly. Below are several strategies that can help push the company toward carbon-neutral operations.

1. Smarter Material Choices

Material selection plays a critical role in embodied carbon. Choosing engineered wood, recycled steel, or low-carbon concrete can dramatically cut emissions. Locally sourced products also reduce transportation impacts. Joy Line’s modular process allows consistent testing and substitution of lower-impact materials without disrupting production schedules, a unique advantage over traditional builders.

2. Advanced Insulation and Air Tightness

Every kilowatt saved is a carbon win. Improved insulation, sealed framing, and thermally efficient windows prevent heat loss and maintain comfort with less energy. Regular blower door testing in the factory can ensure each unit meets performance targets before delivery, resulting in homes that maintain steady temperatures year-round.

3. Electrification and Smart Energy Systems

Transitioning from gas to all-electric systems powered by heat pumps can significantly reduce emissions. When paired with California’s clean energy grid and optional rooftop solar, this shift virtually eliminates operational carbon. Smart thermostats, demand-responsive HVAC systems, and energy management apps can further fine-tune energy use.

4. Renewable Energy Integration

Joy Line Homes’ solar-ready models already anticipate California’s net-zero future. Integrating photovoltaic systems, battery storage, and electric vehicle charging from the start ensures homeowners are equipped for off-grid capability. Over the life of a home, solar power can offset thousands of pounds of carbon emissions annually while lowering energy bills.

5. Factory Efficiency and Recycling

The factory itself can be a hub for sustainability. By reusing materials, recycling scrap, and reducing over-ordering, Joy Line minimizes waste. Process optimization software can track material flows, allowing the company to measure waste diversion rates and continually refine production. Over time, these small operational gains compound into major environmental benefits.

6. Design for Longevity and Flexibility

Designing for durability is one of the most overlooked sustainability strategies. A Joy Line Home that lasts 80 years instead of 40 automatically halves its annual carbon footprint. Modular components also enable easy updates or replacements, extending usability while avoiding full rebuilds. Timeless architecture and quality finishes help these homes remain desirable long after trends fade.

We are based in Santa Cruz County ,

California

Tel: (831) 888-Home

Email: info@joylinehomes.com

Business Hours: 9am - 6pm